The executive director of the Center for Nanoscience and Nanotechnology (CEDENNA), Dr. Juan Escrig, described the entity's participation in the seminar “Challenges and Opportunities in Small Mining” as an “important door for collaboration with small-scale mining. For a Sustainable Development Model”, organized by the Ministry of Mining, Sonami and ANID.

The objective of the conference was to promote collaboration and explore innovative solutions for the future of small-scale mining, highlighting the need to integrate knowledge and technology in pursuit of sustainable development.

On behalf of CEDENNA, they participated together with Dr. Escrig, the Assistant Project Manager, Dr. Omar Daud, and Dr. Álvaro Espejo from the Technology Transfer Line and Director of Technologies at Sistrat, Spin Off born under the wing of the Center and as a consolidation years of research, development and innovation applied to the development of sensors, specially designed to solve problems present in mining.

“Being present at this meeting means opening an important collaboration door between CEDENNA and small-scale mining, which plays a crucial role in our economy and society. The idea is to promote it in a sustainable way through research and innovation”, specified Dr. Escrig.

He added that the meeting generated an enriching space in which ideas, visions and knowledge merged to move towards a more promising future for small-scale mining within a framework of sustainable productive development.

The activity carried out at the offices of the National Mining Society of Chile (SONAMI), was attended by the Minister of Mining, Aurora Williams, the president of the National Mining Society, Jorge Riesco, the director of the National Agency for Research and Development, Alejandra Pizarro, experts from the mining industry and ANID centers.

CEDENNA, at the forefront of mining

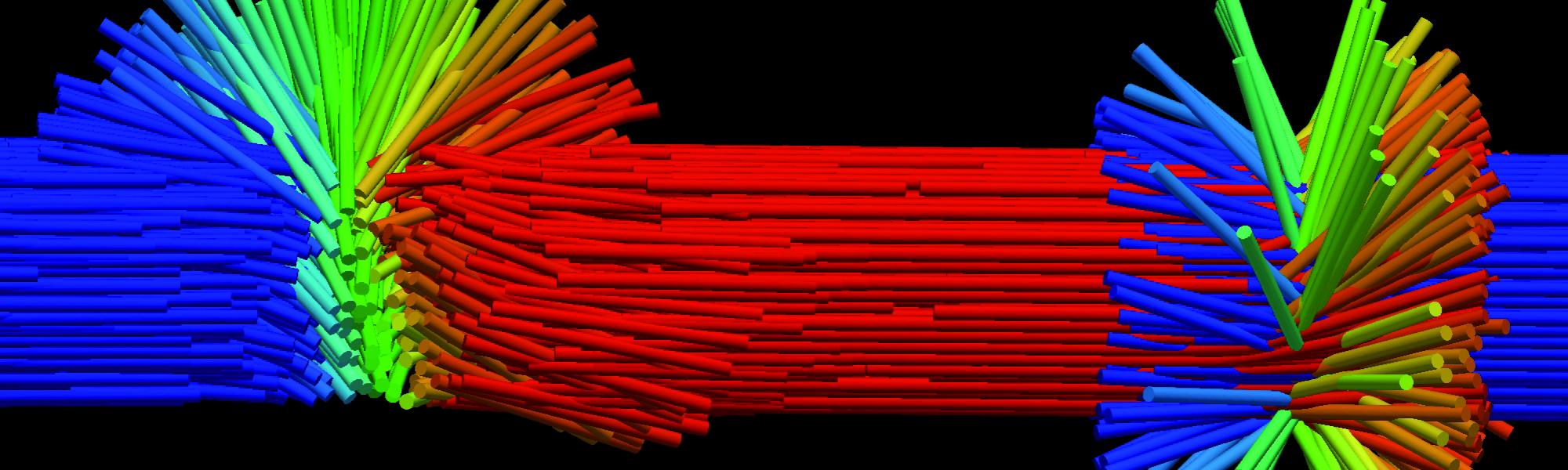

The Nanoscience and Nanotechnology Center is generating research and solutions for the mining sector. One of these developments is the remote monitoring, in real time, of the detachment of unshakeable rocks through sensors installed directly on the GET (mechanical shovel tooth). This solution seeks to solve one of the main problems in the sector and would represent a potential saving of 200 to 400 million dollars a year for Chilean production and up to 3,000 million dollars a year in international production.

When there is a detachment, the system alerts, and therefore that element of wear, will not stop the crusher, avoiding damage and unscheduled stoppages. This project aims for the operator to have an instant warning, in real time, of the detachment of the tooth and, in turn, a simultaneous warning is generated in the "Dispatch". In this way, the operator -and whoever wishes at the site- can know in a timely manner which tooth was lost, and, therefore, carry out rapid maintenance.

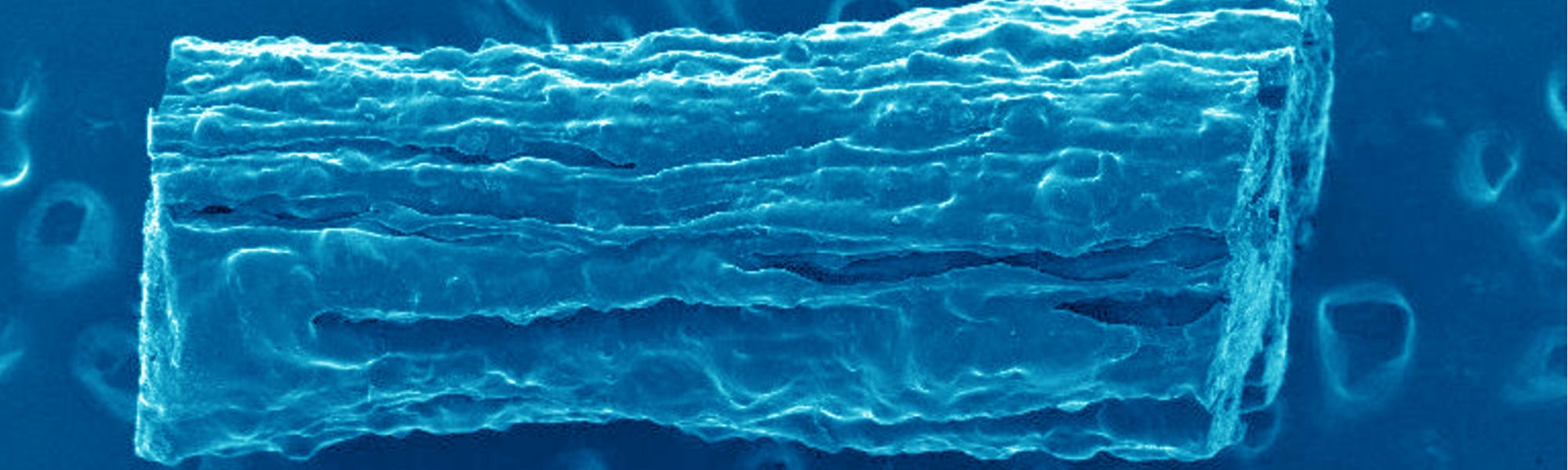

The second sensor is applied to monitoring bushing wear and allows optimizing its useful life, making the most of its performance. Mining operations are tremendously hard, the materials wear out, particularly the bushings. And this wireless monitoring system makes it possible to measure, also in real time, the level of wear of these parts. And in turn, it makes it possible to optimize its useful life, planning its replacement in an efficient and timely manner.

- Log in to post comments